Type of course:

Digital learning, Lesson

Language:

EN

Duration:

15 minutes

Workload:

10 hours

Proficiency:

Intermediate

Target:

Manager, Professionals, Students

SUMMARY

Welcome to the TFKN+, “Critical Resources and Remanufacturing” Lesson!

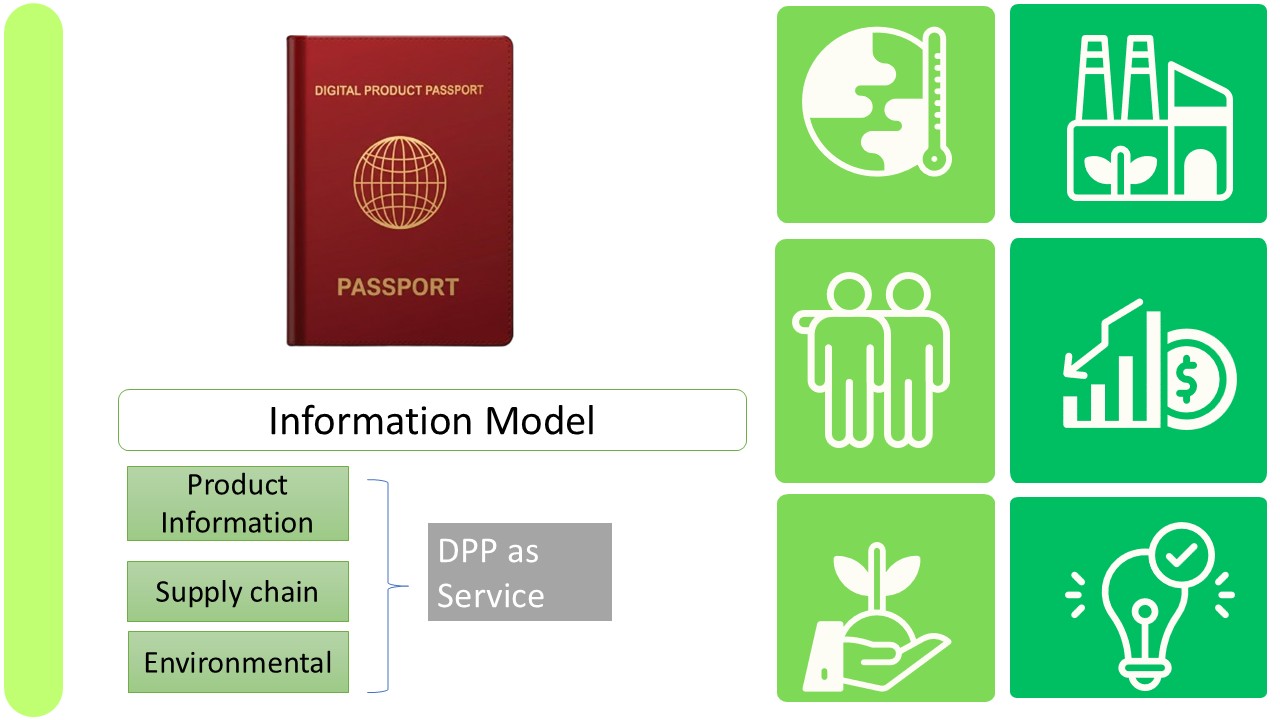

This lesson explores the importance of critical raw materials (CRMs) in modern manufacturing, highlighting their economic significance and associated supply chain risks. It outlines the EU’s strategic approach to classifying, monitoring, and securing CRMs, particularly for high-value industries. Moreover, it explains how additive manufacturing (AM) and remanufacturing contribute to sustainability by reducing raw material consumption, extending component lifespans, and strengthening supply chain resilience.

Moreover, feel free to explore a wide array of videos, articles, papers and books, in the extra materials part of the lesson. Let us get started!

About The Author

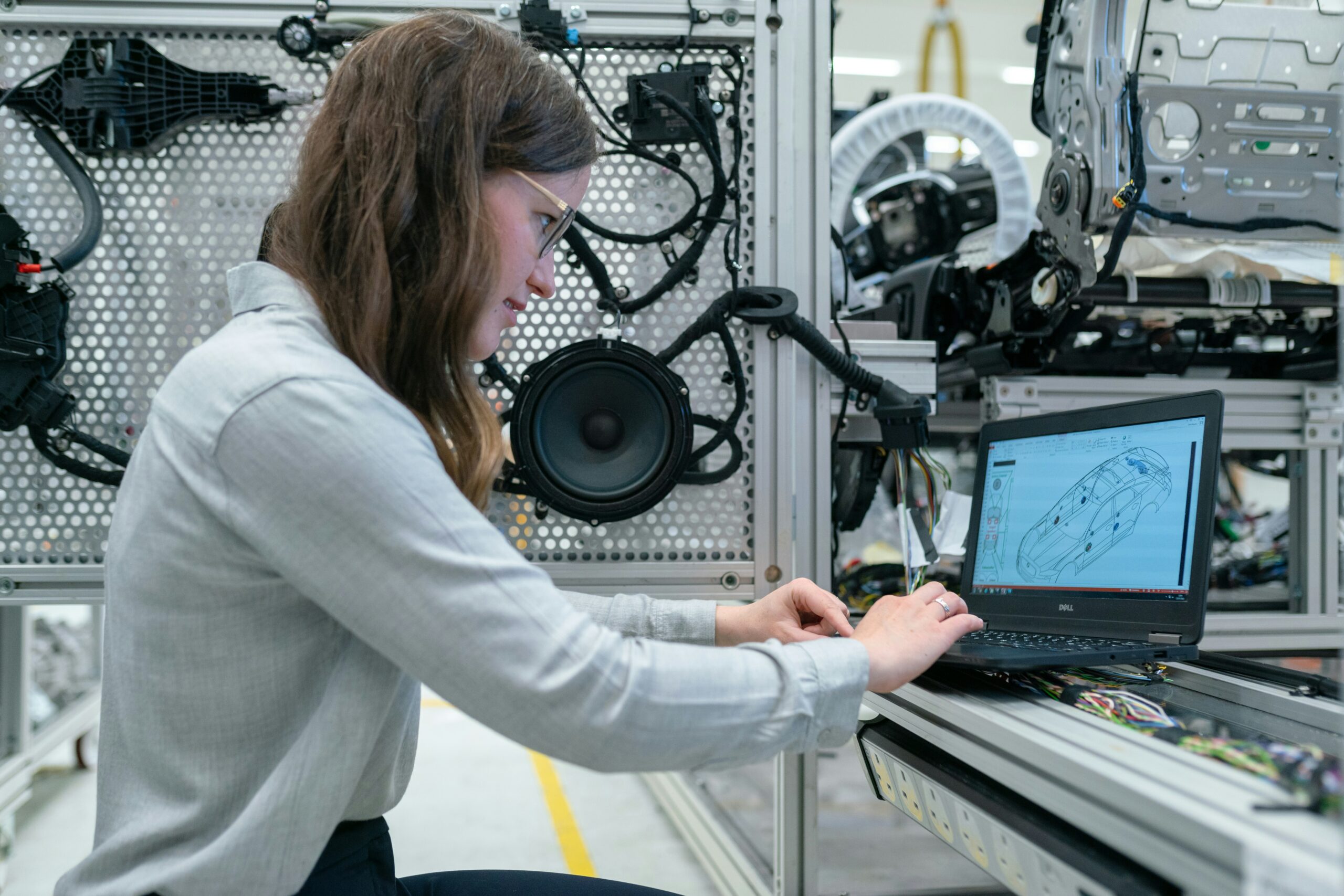

MADE is a Competence Center for Industry 4.0 created to implement Orientation, Training, and Finalization activities for technology transfer projects with companies on Industry 4.0 issues. The ultimate goal of the Competence Center is to keep the profile of companies high, competitive, and sustainable. Moreover, MADE supports manufacturing companies, especially small and medium enterprises, on the path of digital transformation to factory 4.0: smart, connected, and sustainable, by providing a wide range of knowledge, methods and tools on digital technologies.

The Laboratory for Manufacturing Systems & Automation (LMS) is oriented on research and development in cutting edge scientific and technological fields. LMS is involved in a number of research projects funded by the CEU and European industrial partners. Particular emphasis is given to the co-operation with the European industry as well as with a number of “hi-tech” firms.

Learning outcomes

- After the end of the lesson, learners will be able to define and classify EU Critical Raw Materials (CRMs), identify key materials used in strategic sectors, explain their industrial significance, and recognize the associated supply risks and geopolitical dependencies.

- After the end of the lesson, learners will be able to understand the role of Additive Manufacturing (AM)—with a focus on Directed Energy Deposition (DED) and Hybrid AM—in optimizing CRM usage and minimizing waste.

- After the end of the lesson, learners will be able to explain how AM and remanufacturing contribute to sustainability by reducing raw material consumption, extending component lifespans, and strengthening supply chain resilience.

Course Content

Topics

Advanced Manufacturing, Sustainable Manufacturing

![[TFKN+] A03a - Critical Resources in Remanufacturing](https://eitmanufacturingacademy.eu/wp-content/uploads/2024/12/Slide2-3-scaled.jpg)