Type of course:

Digital learning, Lesson

Language:

EN

Duration:

10 minutes

Workload:

2 hours

Proficiency:

Beginner

Target:

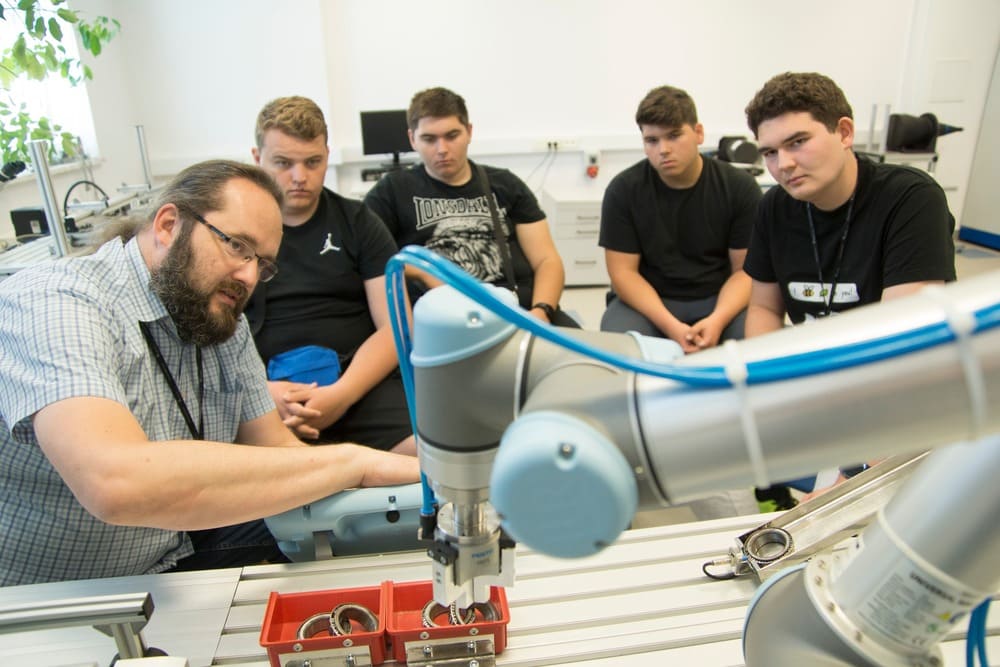

Professionals, Students, Workers

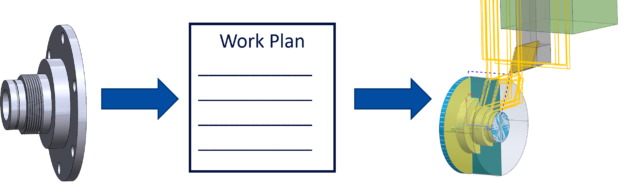

This course presents the methodology for selecting feed per revolution and depth of cut in turning processes to ensure chip breakage and consequently avoid chip nests. The turning operations are continuous chip operations. This means that the generated chip due to the machining process could be uninterrupted. This feature is tremendously dangerous by the chip temperature, the chip nest that can be tangled around the workpiece and the poor surface quality.

Learning outcomes

- The student will be able to identify the geometries that correspond to the chip breaker.

- The student will be able to evaluate the cutting conditions suitable for chip breaking in turning.

- The student will be able to estimate the effect of the cutting conditions and the shape of the chip in turning.

Course Content

Topics

Advanced Manufacturing, Transversal Skills, CNC Machining, Mechanics, Manufacturing for Pupils

Content created in 2023

Related

Login

Accessing this course requires a login. Please enter your credentials below!