Type of course:

Digital learning, Path

Language:

EN

Duration:

1 hour

Workload:

6 hours

Proficiency:

Intermediate

Target:

Manager, Professionals, Students, Workers

SUMMARY

This course explores critical resource management in the context of remanufacturing, focusing on reverse logistics, closed-loop systems, and the implications for core collection in remanufacturing. It also covers the identification of EU critical materials and the regulatory frameworks surrounding remanufacturing. Additionally, learners will examine emerging business models related to remanufacturing, such as distributed manufacturing, product-service systems, and servitization, while considering sustainability implications. Topics include supply chain management, EU critical materials, and the business models shaping the future of remanufacturing.

The course includes the following lessons:

- Critical Resources in Remanufacturing

- Critical Resource Management & Manufacturing Megatrends

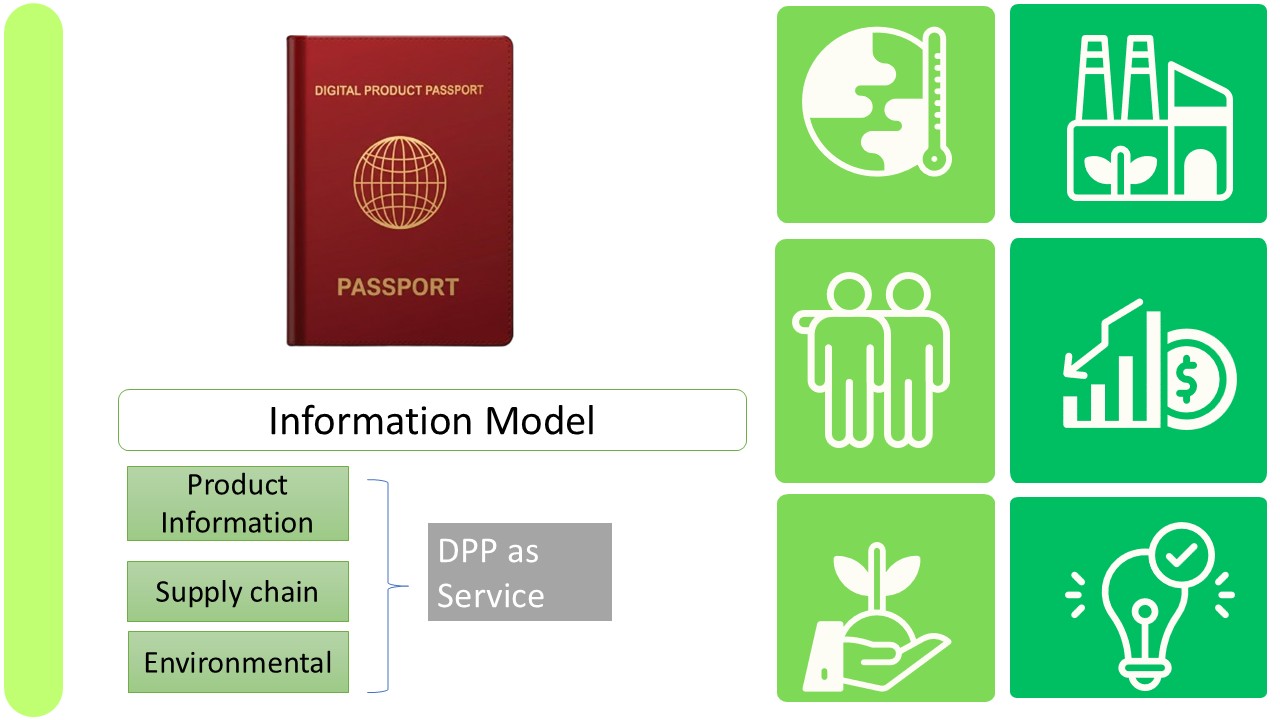

- Remanufacturing Business Models

- Remanufacturing Regulatory Frameworks

- Summative Assessment

About The Author

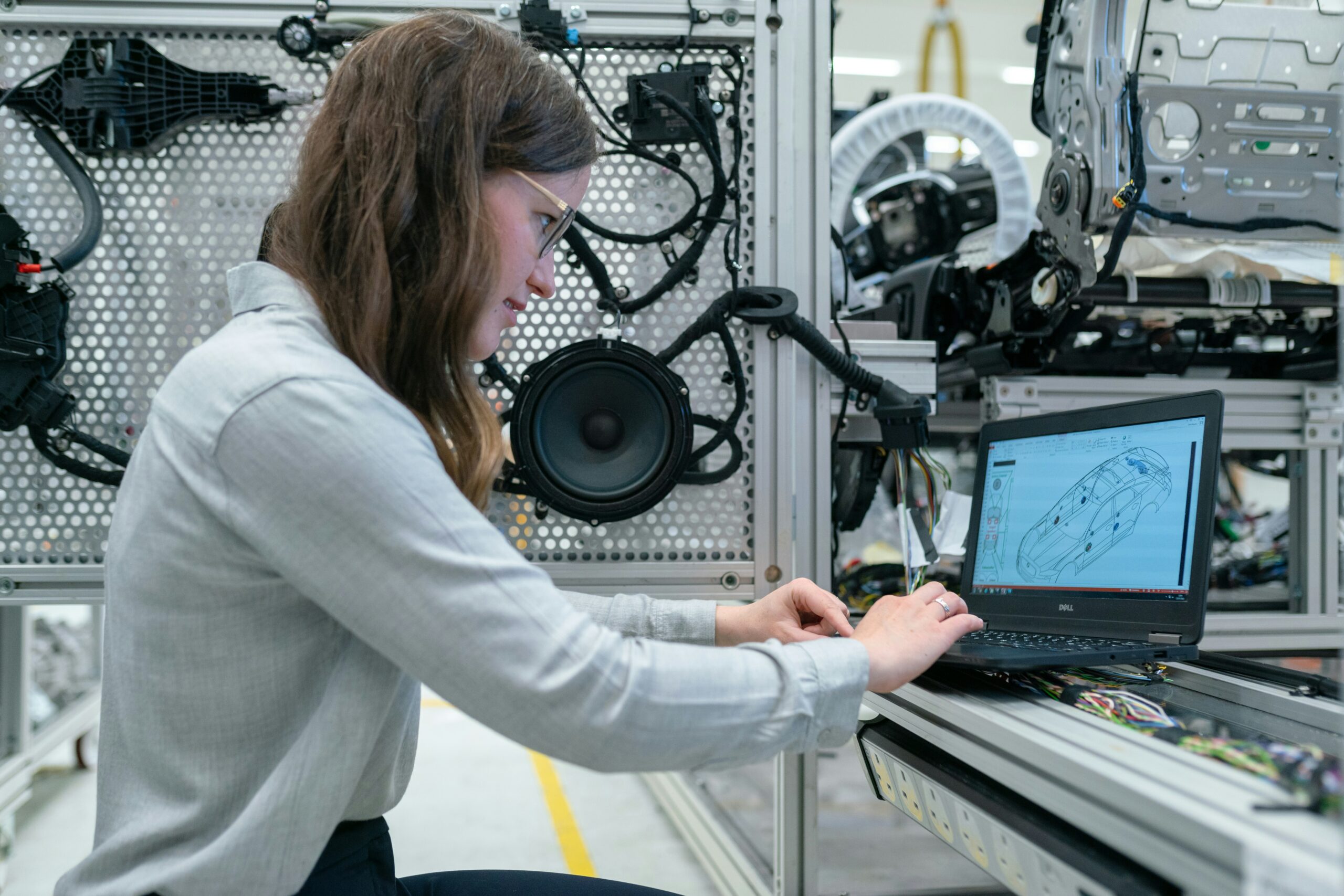

MADE is a Competence Center for Industry 4.0 created to implement Orientation, Training, and Finalization activities for technology transfer projects with companies on Industry 4.0 issues. The ultimate goal of the Competence Center is to keep the profile of companies high, competitive, and sustainable. Moreover, MADE supports manufacturing companies, especially small and medium enterprises, on the path of digital transformation to factory 4.0: smart, connected, and sustainable, by providing a wide range of knowledge, methods and tools on digital technologies.

The Laboratory for Manufacturing Systems & Automation (LMS) is oriented on research and development in cutting edge scientific and technological fields. LMS is involved in a number of research projects funded by the CEU and European industrial partners. Particular emphasis is given to the co-operation with the European industry as well as with a number of “hi-tech” firms.

Learning outcomes

- Translate critical resource management through the scope of remanufacturing, focusing on reverse logistics, closed-loop systems, implications on core collection for remanufacturing and identify EU critical materials.

- Classify re-man regulatory frameworks and explore emerging business models relating to re-man, including distributed manufacturing, product-service-systems and servitization.

Topics

Advanced Manufacturing, Remanufacturing, Automation and Robotics, Sustainable Energy and Clean Technologies, Sustainable Manufacturing, Additive Manufacturing, CNC Machining

![[TFKN] A03: Emerging Business Models, Critical Resource Management and Re-man Regulatory Frameworks](https://eitmanufacturingacademy.eu/wp-content/uploads/2024/07/759-5-4254-Leadership-Development-for-Women-in-Manufacturing-LP-Quiz-pexels-vlada-karpovich-4050320.jpg)