Type of course:

Digital learning, Path

Language:

EN

Duration:

2 hours

Workload:

20 hours

Proficiency:

Intermediate

Target:

Professionals, Workers

The 5th Industrial Revolution (5IR) is the next stage in the evolution of industry and technology. It is expected to bring significant changes to the way we live, work, and interact with the world around us. The main concepts of 5IR include the integration of technology and humans, the use of advanced materials, and the development of new energy sources.

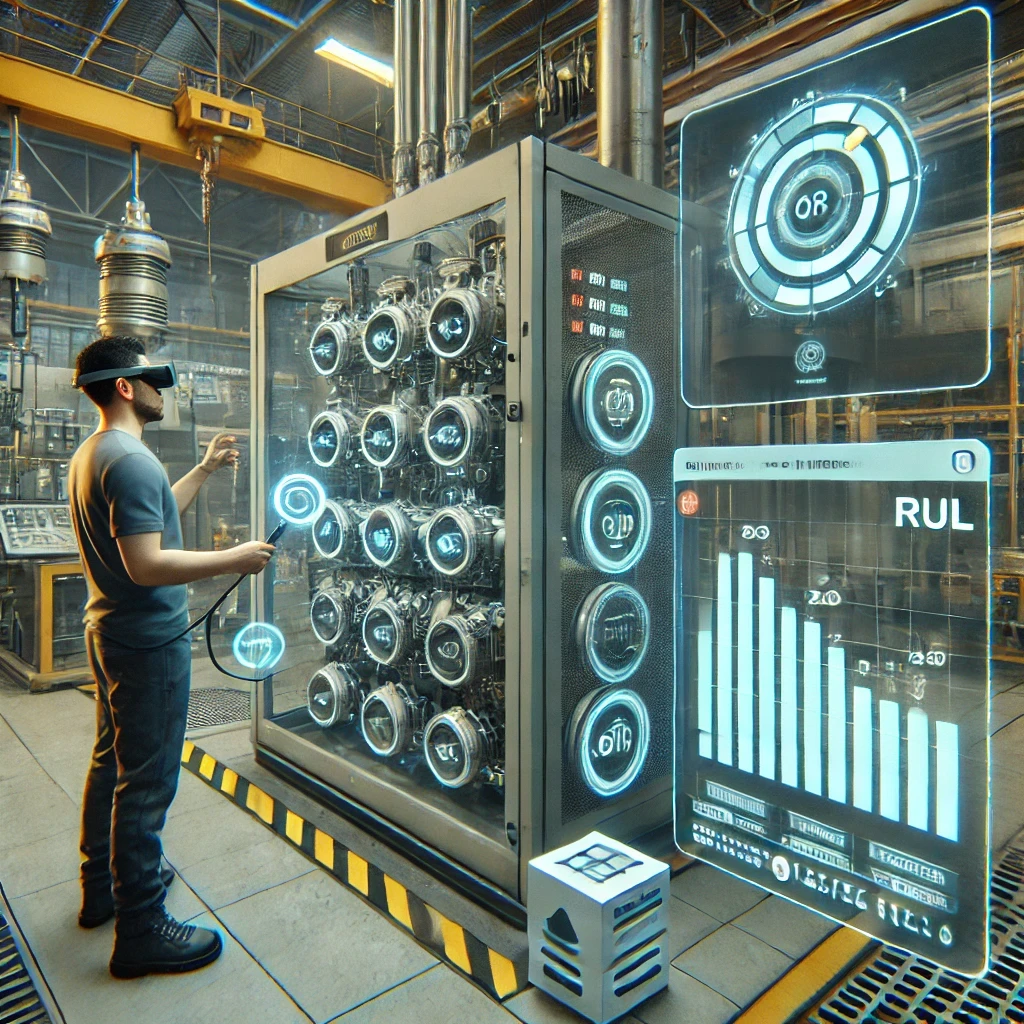

One of the key drivers of 5IR is the Internet of Things (IoT), which refers to the interconnectivity of devices and systems, enabling real-time data sharing and analysis. This will lead to more efficient and automated processes, and enable the creation of new business models.Another major aspect of 5IR is the rise of artificial intelligence (AI), which will enable machines to learn and make decisions based on data. This will lead to more personalized products and services, and greater efficiency in industries such as healthcare, transportation, and manufacturing.Advanced materials such as nanomaterials, graphene, and advanced composites will also play a significant role in 5IR. These materials offer unique properties such as high strength, flexibility, and conductivity, which can be used to create new products and applications.Finally, 5IR will also involve the development of new energy sources, including renewable energy and new forms of storage. This will enable a transition to a more sustainable and environmentally-friendly economy.In summary, the 5th Industrial Revolution represents a new era of technological advancement that will impact every aspect of our lives. Its key concepts include the integration of technology and humans, the use of advanced materials, and the development of new energy sources.

Learning outcomes

- After the training, learners are able to demonstrate a clear understanding of the fundamental principles and key components that define Industry 5.0, including cyber-physical systems, Internet of Things (IoT), big data analytics, artificial intelligence, and human-machine collaboration.

- After the training, learners are able to evaluate the potential benefits and challenges associated with the adoption and implementation of Industry 5.0 in various industries, by gaining insights into increased automation, improved productivity, enhanced flexibility, and the implications for the workforce, such as upskilling and job transformations.

- After the training, learners are able to identify opportunities for implementing Industry 5.0 technologies and strategies in manufacturing processes, supply chains, and production systems and assess the impact of Industry 5.0 on business models, customer experiences, and overall industry competitiveness.