Type of course:

Digital learning, Path

Language:

EN

Duration:

1 hour

Workload:

6 hours

Proficiency:

Intermediate

Target:

Manager, Professionals, Students

SUMMARY

Replace this text by writing here a summary of the course you are creating. Consider that the users will read the short description of the training first and then come to read this summary. So start this text by recalling the one you wrote in the short description. Explain what this course is about, what its aim is, and why it is interesting for the learners.

Use an engaging style to attract the learners’ attention; for example, you could:

- Pose a thought-provoking question to stimulate curiosity;

- Include a powerful quote that encapsulates the theme of the course;

- Address the reader directly to make them feel involved.

About The Author

Replace this text with key information on the author(s) of this lesson. Include their academic and professional background and experience. The purpose of this text is to demonstrate accountability: the authors are experts on the topics covered in the lesson.

1. Needs, benefits, applications & limitations of die-less forming

1.1. Needs

In this modern era, developments and advancements in sectors such as automobile, aerospace, medical and other are shifting towards make-to-order manufacturing, requiring the adoption of advanced technologies. Furthermore, manufacturing industries need to face the recent customer-oriented requirements for affordable and tailored products. So, industries need to utilize flexible, autonomous manufacturing systems, able to adapt to the dynamic demands with real-time control on the shop floor. Incremental Sheet Forming (ISF) stands out as a key solution, enabling batch-type production, make-to-order manufacturing, and the remanufacturing of complex, obsolete parts, all with reduced lead times and lower costs.

1.2. Benefits

The ISF process offers several benefits compared to the conventional sheet metal forming processes, due to its nature. The benefits are the following:

- Completely die-less process.

- Suitable for rapid prototyping and testing.

- Usable parts can be formed directly from CAD data.

- Forming non-symmetrical components.

- Increased material formability.

- Smaller forming forces required.

- Shorter production time.

- Lower costs, as no fixed dies are required, and simple tooling can be utilized.

- Able to ramp up the production at the first stages.

- No need for dedicated machine tools, as conventional CNC milling machines and industrial robots can be used.

- High degree of automation, enabling easy and quick design changes.

1.3. Applications

There is a variety of leading sectors where ISF is utilized to produce complex, tailor-made components. The major industries are shown in Table 1, along with a few of their respective ISF applications. Also, some typical components produced with ISF are shown in Figure.

| INDUSTRY | EXAMPLES |

| Automotive | Fenders, bonnets, doors, headlight housings, bullet train parts, frame for silencer of trucks |

| Aerospace | Wing structures, aviation components, structural element in flight control systems |

| Medical | Cranial implants, ankle implants, clavicle implants, denture bases |

| Architectural | Customized interiors, art pieces, ceiling designs |

| Household | Culinary appliances, customized floors, customized ergonomic chairs |

| Electronics | Cellular phone body, integrated Circuit LED frames, hard disk drives, sensors. |

1.4. Limitations

Despite the benefits the ISF process offers, it remains an emerging technology facing several limitations. These limitations pose barriers to achieving commercial acceptance of this die-less technology at an industrial scale. The following are the major limitations of ISF technology:

- Low level dimensional accuracy and surface finish.

- Not suitable for mass production of components.

- Difficulty to produce vertical walls.

- More forming time is required to form a component.

- Unwanted sheet-bending.

- Greater springback effect.

- The mechanism of this technology is debatable that needs to be solved by researchers.

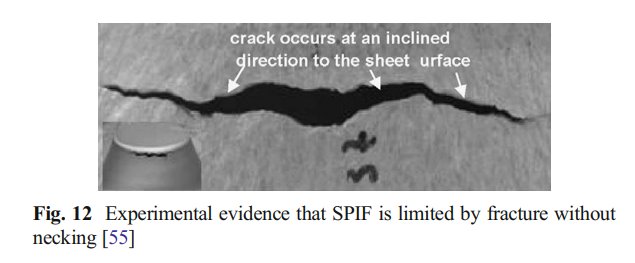

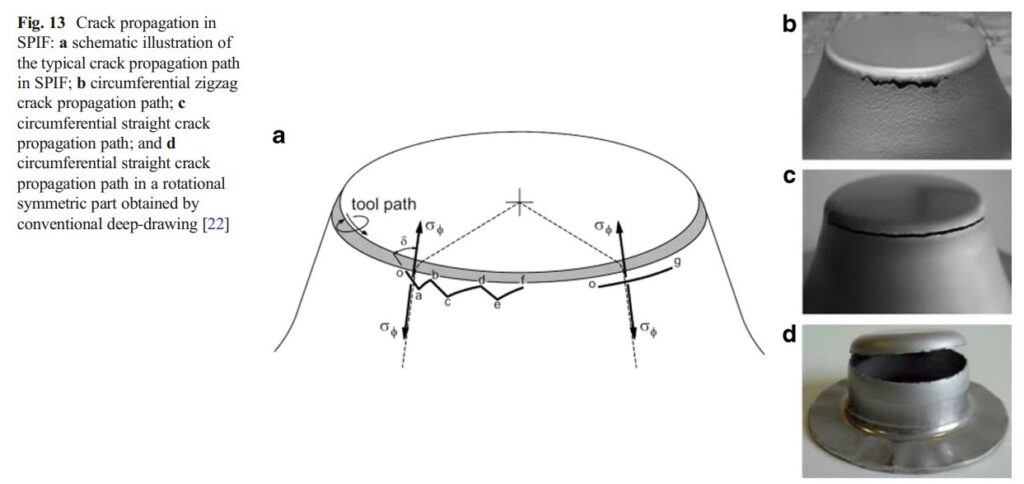

- Interactions between input parameters of this process are quite cumbersome which sometimes leads to material failure.

- Finite element (FE) simulations of this process are time-consuming and complex.

- The relationship between forming-force and stress–strain patterns is still questionable.

- The anisotropic behaviour and structural integrity of the formed components are inconclusive.

- The optimization of layout of each variant of the process is not exhaustive yet.

- The consistent changing of the ISF technologies is also a barrier in defining the common guidelines regarding the process.

2. Incremental Sheet Forming (ISF)

The ISF process is characterized by progressively applying plastic deformation to sheet material, with a forming tool that is maneuvered by a computer numerical control (CNC) action on a milling machine or by an industrial robot. The forming tool performs the incremental localized deformation of the sheet while moving along a predefined trajectory, descending a small step in each contour.

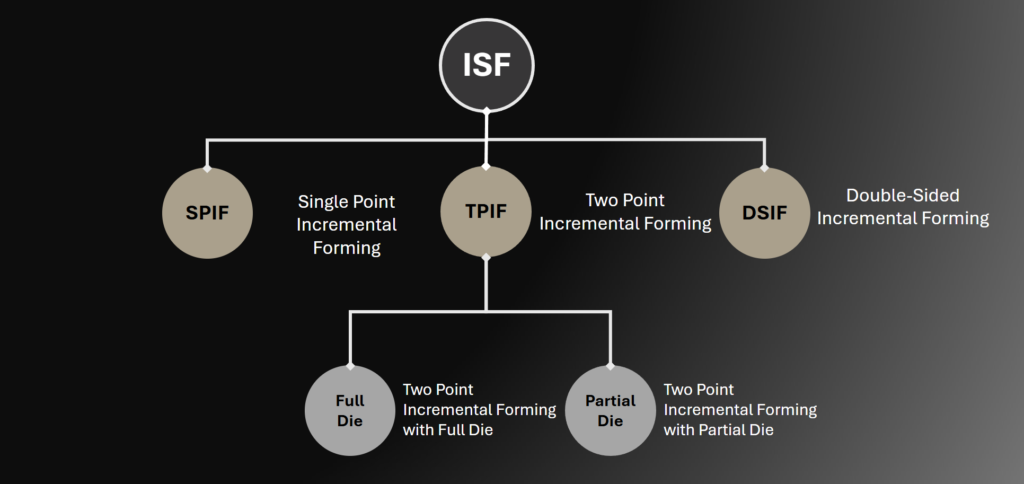

The ISF process can be broadly classified on the basis of the forming method, strategy, machinery etc. According to the forming method, the process can be distinguished into single-point incremental forming (SPIF), two-point incremental forming (TPIF) and double-sided incremental forming (DSIF) forming processes.

2.1. Single-Point Incremental Forming (SPIF)

In Single-Point Incremental Forming (SPIF) the blank is simply clamped into a hollow fixture at its perimeter and a simple forming-tool (generally of spherical shape) is moved over the sheet in a horizontal plane with a definite feed and predetermined toolpath. The path of the forming-tool is controlled by NC instructions that are normally generated using suitable CAM packages (Del-CAM, UG-NX, etc.). The sheet is pressed by the forming-tool into a vertical downward direction after completing each contour along the horizontal plane. The amount that the sheet is pressed after each contour is termed the step-down size. This parameter (step-down size) is crucial for determining the formability and geometrical accuracy of the components.

2.2. Two-Point Incremental Forming (TPIF)

Two-point incremental forming (TPIF) can be classified into two categories according to the type of die is used to form the part. The two types of dies are the partial and the full die. In the process, the partial or the full die is employed to the opposite side of the forming-tool to provide support to the metal sheet. The lower surface of the sheet remains in direct contact with the support. In TPIF, the sheet is supported at its center only and its perimeter moves in a vertical downward direction along with the tool movement. The forming tool moves from the inside outwards in a planar motion. Step depth is executed by the forming-tool contour by contour in the vertical downward direction synchronously with the perimeter of the sheet.

The benefits and the limitations of TPIF are listed below:

- Produces convex shapes.

- Quick design changes are not possible due to the involvement of specific dies.

- Poor flexibility, because a new die is needed for producing each new part.

- Increase in cost.

- Higher production time than SPIF.

2.3. Double-Sided Incremental Forming (DSIF)

In Double-Sided Incremental Forming (DSIF), two forming tools are deployed on both sides of the sheet to produce local deformation. Both forming-tools move synchronously, producing either a convex or a concave shape, and if both forming-tools are moved independently, a wrap surface (concave and convex shapes on the same sheet) can be produced. In the latter case, both tools are moved along predetermined paths; the forming-tools are able to form the sheet in two areas simultaneously.

The benefits and the limitations of DSIF are listed below:

- Produces both convex and concave shapes.

- Produces both axisymmetric and asymmetric shapes.

- Greater formability and dimensional accuracy as compared to SPIF and TPIF.

- No backing-plate required

- More flexible and agile than the TPIF process.

- Inaccurate thickness prediction.

2.4. Multi-Stage Incremental Forming (MSIF)

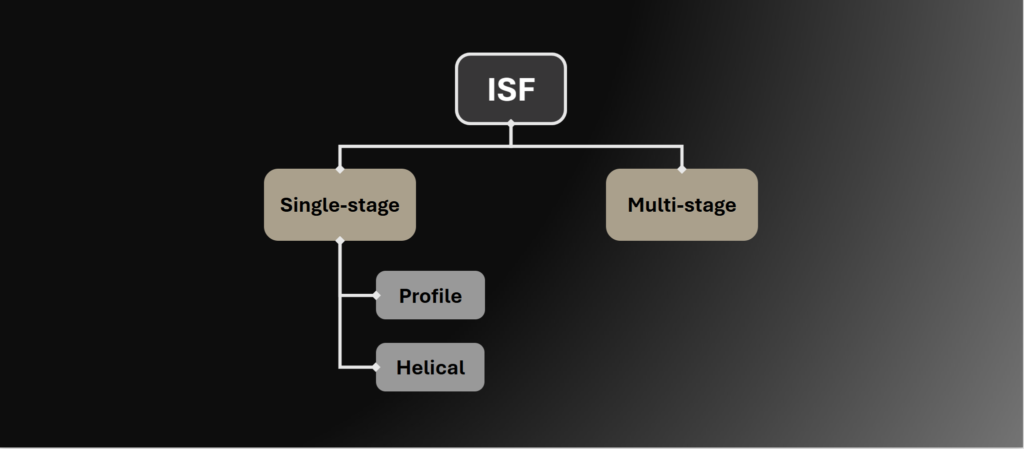

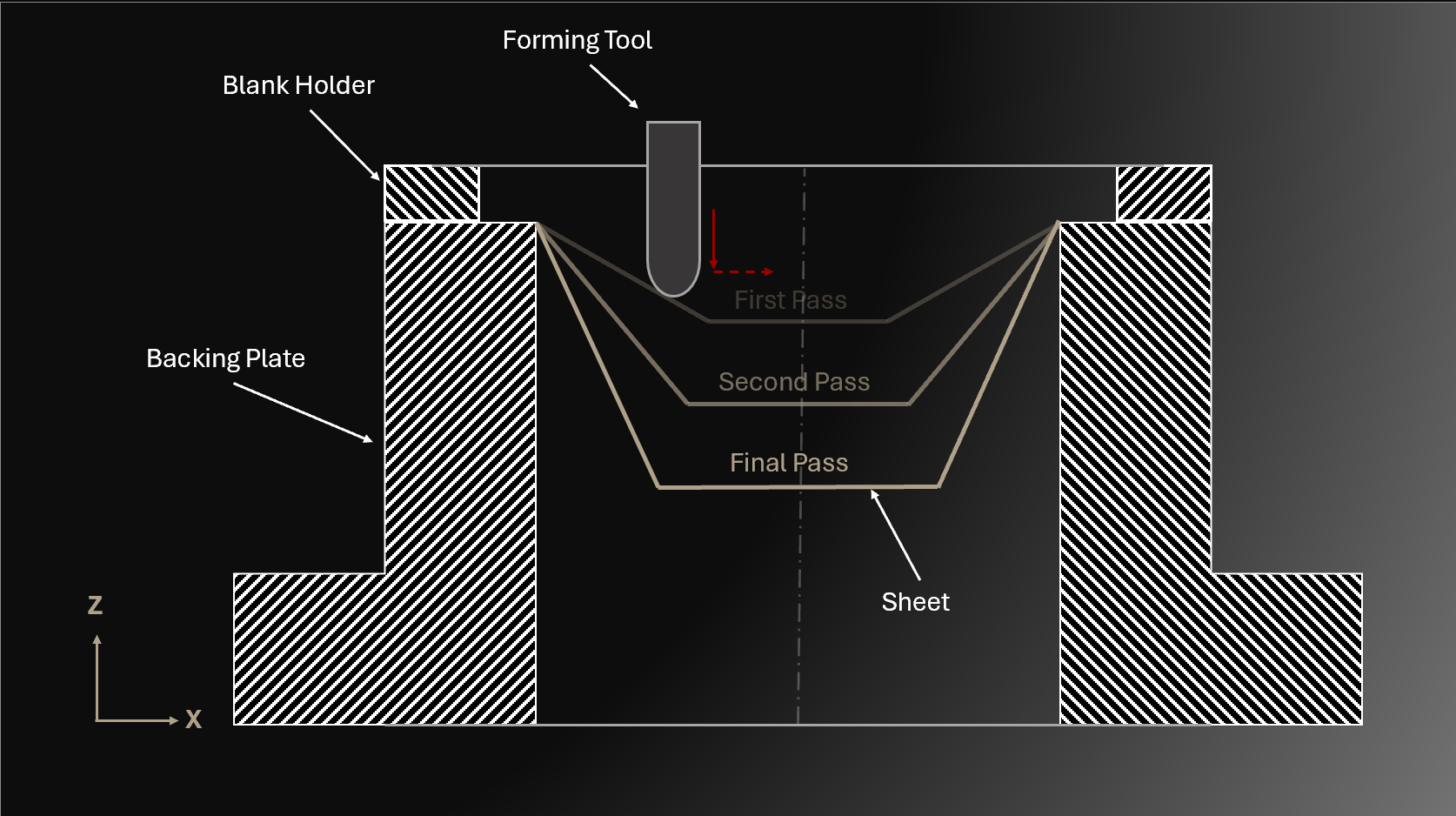

As mentioned earlier ISF can be classified also based on the forming strategy, to single-stage and multi-stage. The single stage incremental forming can be realized either with a profile strategy or with a helical.

The basic principle of MSIF is to use the increase of passes to transfer the material that should be at the bottom of the part (non-deformation area or small deformation area) to the large deformation area of the part. Firstly, it is formed into a shape with a smaller forming angle, and after the processing is completed, the forming angle is increased for the subsequent forming, and so on, until it is formed to the final shape.

The benefits and limitations of MSIF are listed below:

- Able to deform more materials

- Reduces material thinning

- Improves parts’ wall thickness distribution.

- Obtains straight-walled parts.

- Requires reasonable material flow control.

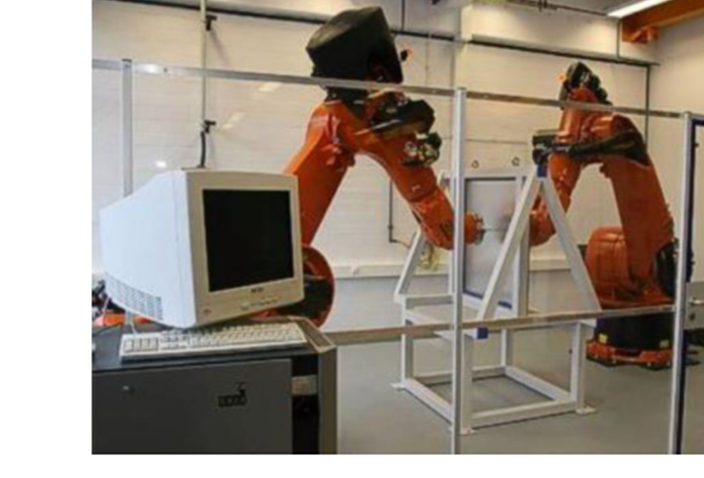

2.5. Roboforming

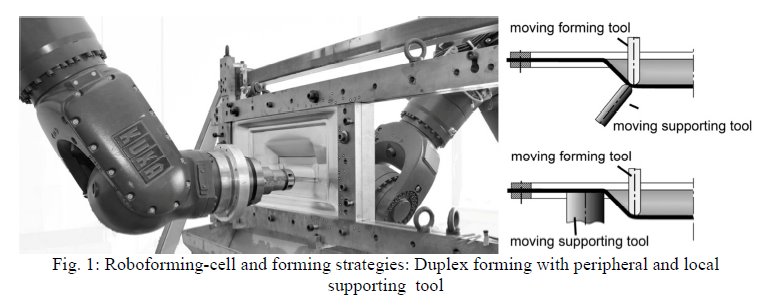

In Roboforming, two synchronized industrial robots (master robot and slave robot) are equipped with a sphere-tipped tool. The metal sheet is held between the master robot and slave robot. The master robot moves incrementally on the sheet which deforms the sheet in the shape of the toolpath and the slave robot provides support to the master robot from the opposite face of the sheet. This process is also known as robot assisted incremental sheet forming

The benefits and limitations of MSIF are listed below:

- Able to manufacture large parts

- Positioning accuracy

- Robot compliance

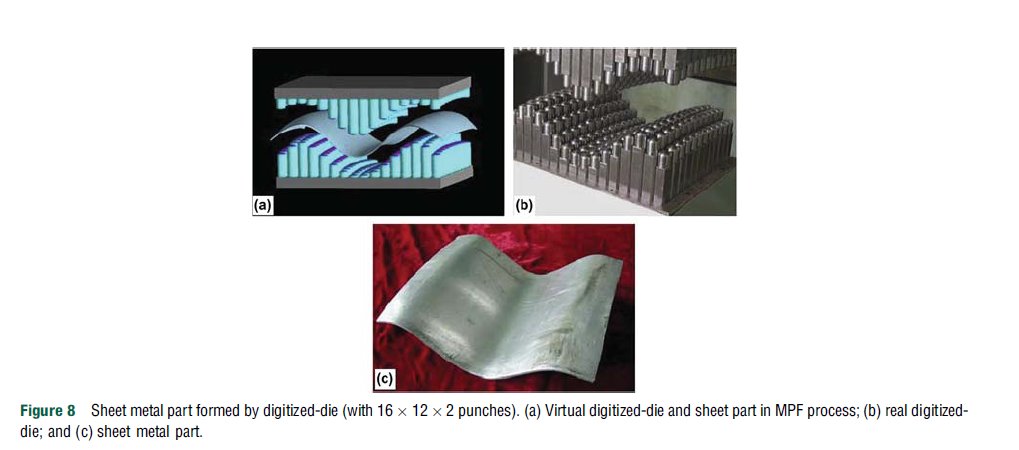

2.6. Multi-Point Forming (MPF)

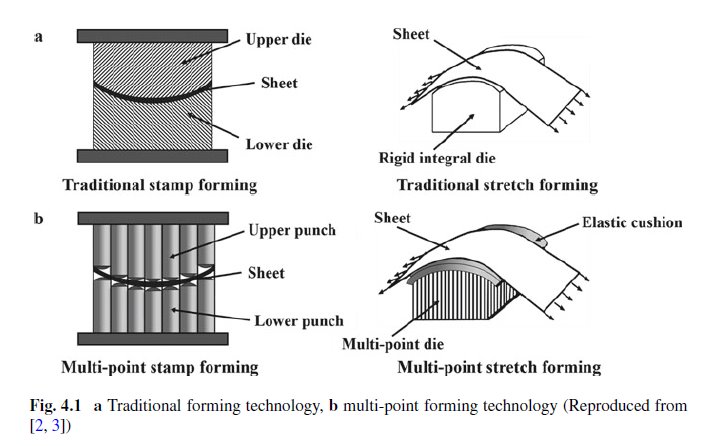

Multi-Point Forming (MPF) is an advanced and flexible sheet metal forming technology where a reconfigurable die is used to produce parts of various shapes. The basic idea behind MPF is to divide the curved surface of the traditional die into many discrete pins, using punch elements instead of traditional dies. The MPF technology can be used to form a variety of curved part shapes without the need for solid dies, by adjusting the height of the punch elements in both the upper and lower parts of the press. Each element of the die can be individually controlled by a computer, allowing precise adjustments to small sections of the curved surface. It is obvious, that finer the punch and smaller the spacing between the punches, the better is the surface approximation.

The benefits and limitations of MPF are listed below:

- Able to manufacture large parts in small presses

- Wrinkles

- Dimples

- Thickness variations

- Springback effect

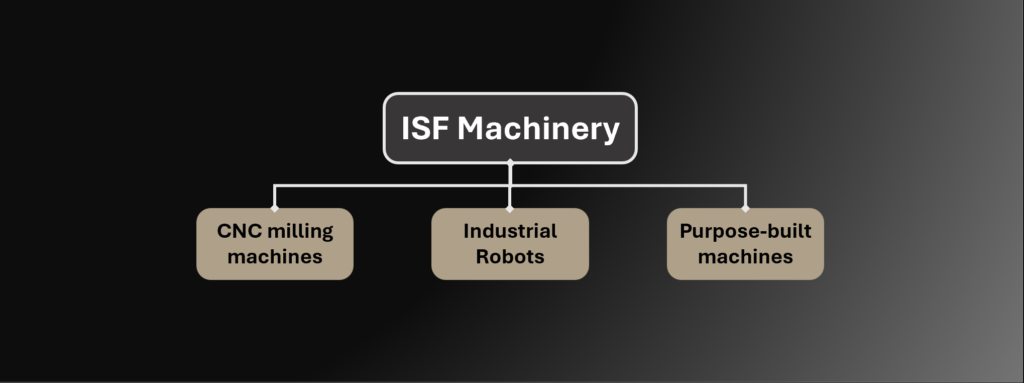

2.7. Machinery

The forming machinery for the ISF process can be divided into three categories

2.7.1 CNC milling machines

CNC milling machines are widely used for the ISF process due to the following benefits:

- High stiffness (approx. 200 kN/mm)

- High load capacity

- Large working area

- Moderate feed-rate

- High flexibility

- High accuracy

- Best suited for SPIF and TPIF processes

2.7.2. Industrial Robots

The ISF process can also be executed using heavy-duty industrial robots. The use of robots for the ISF process increases the flexibility of the process tremendously, but the lower stiffness of industrial robots limits their forming capacity.

Using an industrial robot as a forming machine allows the forming-tool to be moved and positioned at various angles relative to the workpiece, enabling the accurate and easy production of complex shapes. A robot has more DOFs than a milling machine, providing better and more accurate control of toolpaths, thus increasing the flexibility of the forming machinery. In addition, a high feed-rate and large working area enable the production of larger components at a faster rate, eliminating the major limitation of the lower production rate of the ISF process.

Although industrial robots offer the above advantages for the ISF process, the following drawbacks have been observed by researchers in comparison to CNC milling machines:

- Lower range of stiffness (0.1–120 kN/mm)

- Less load capacity

- Less accuracy

2.7.3. Purpose-built machines

Considering the above factors, special machines for ISF, called purpose-built machines, have been developed:

- Amino ISF machine

- Cambridge ISF machine

- SPIF-A machine

ISF purpose-built machines has the following features:

- Better accuracy than adapted CNC milling machines and industrial robots

- Higher load capacity in the axial direction of the forming-tool

- Equipped with partial die set-up as required in TPIF

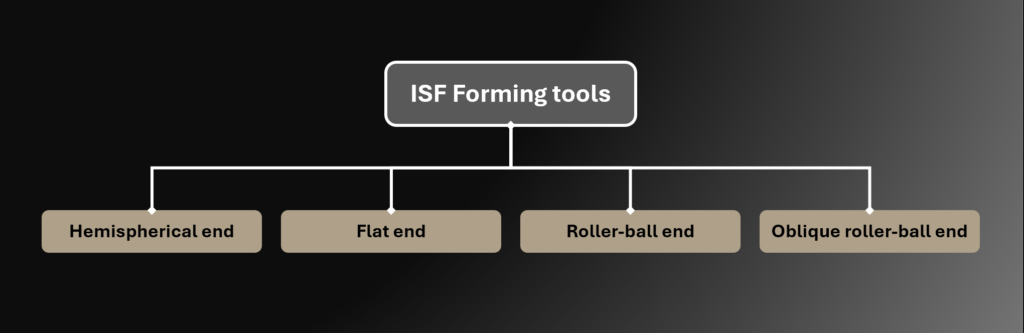

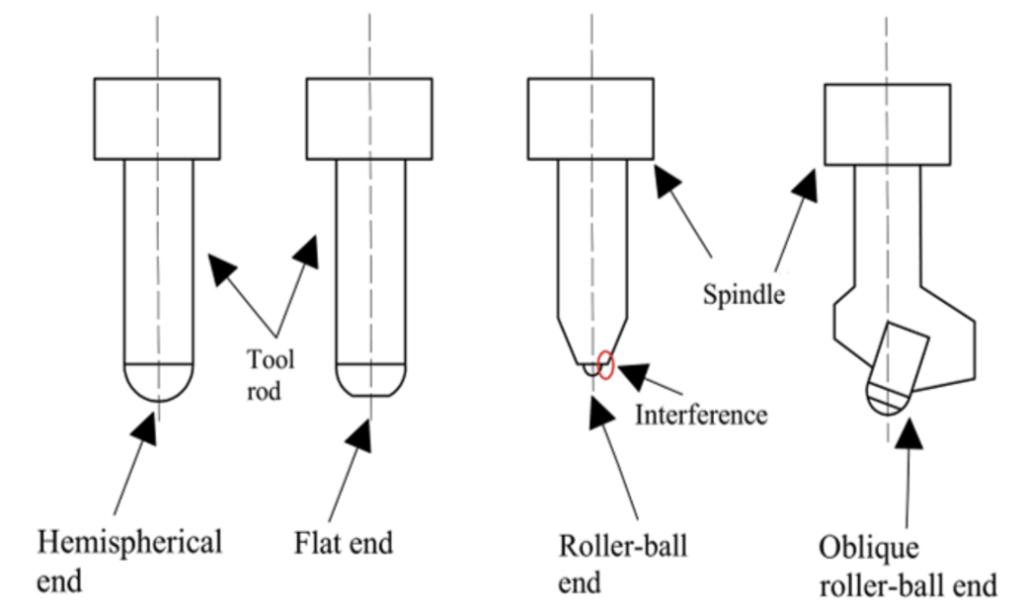

2.7.4. Forming Tools

The forming tool and specifically its geometry is a crucial parameter in the ISF process that affects the forming force required to deform the material, the surface roughness, the strains and the formability of the formed parts. The following are the common types of forming tools used in ISF.

3. Commercial Technologies Showcase

In this section of the lesson, several commercialized technologies related to incremental sheet forming will be presented. In the field of roboforming, Machina Labs has developed an advanced and agile manufacturing platform that integrates 7-axis robots, known as Machina’s Robotic Craftsman. In the area of ISF using CNC milling machines, Desktop Metal has made significant advancements by developing

3.1. Machina Labs

3.2. Figur Digital Sheet Forming Technology

3.3. KIKUKAWA/MECO – eurecat

3.4. StilFold

Learning outcomes

- Recognize the recent advancements in sheet metal forming technologies, including the need, impact and limitations of flexible die-less forming technologies.

- Describe the process mechanisms, potential applications and production capabilities of advanced forming technologies, including Multiple Point Forming, Incremental Sheet Forming, Robotic Incremental Sheet Forming and “Industrial Origami” Stilfold curve folding.

Topics

Advanced Manufacturing, Automation and Robotics, Sustainable Manufacturing

![[MFAC A-02] Innovations in flexible Sheet Metal Forming Technologies V0.1 (obsolete)](https://eitmanufacturingacademy.eu/wp-content/uploads/2024/07/759-5-4254-Leadership-Development-for-Women-in-Manufacturing-LP-Quiz-pexels-vlada-karpovich-4050320.jpg)